Melt blown describes a process by which nonwoven materials can be manufactured directly from granules. A special spinning process in conjunction with high-speed hot air is utilised in the production of fine-fibred materials of varying structure. These materials are of excellent quality, versatile and easily processed.

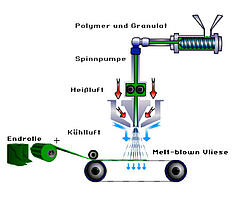

The meltblown process

Granules melted in an extruder are fed directly via a viscose pump to the nozzle block. Following discharge from the nozzle tip, the polymer is stretched by means of compressed, hot process air. The resultant microfibre web is placed on an air-permeable screening belt. For laminate manufacture, the melt-blown unit is extended by an uncoiler in front of and behind the nozzle, with a calander for bonding the fed materials. In this manner, material consisting of single, double or multiple layers is produced. For optimal further processing, the trimmed and cut-to-size microfibre web is wound by a winder. The entire unit is equipped with a high-performance control system.